Bayanin Samfura

Ƙayyadaddun bayanai

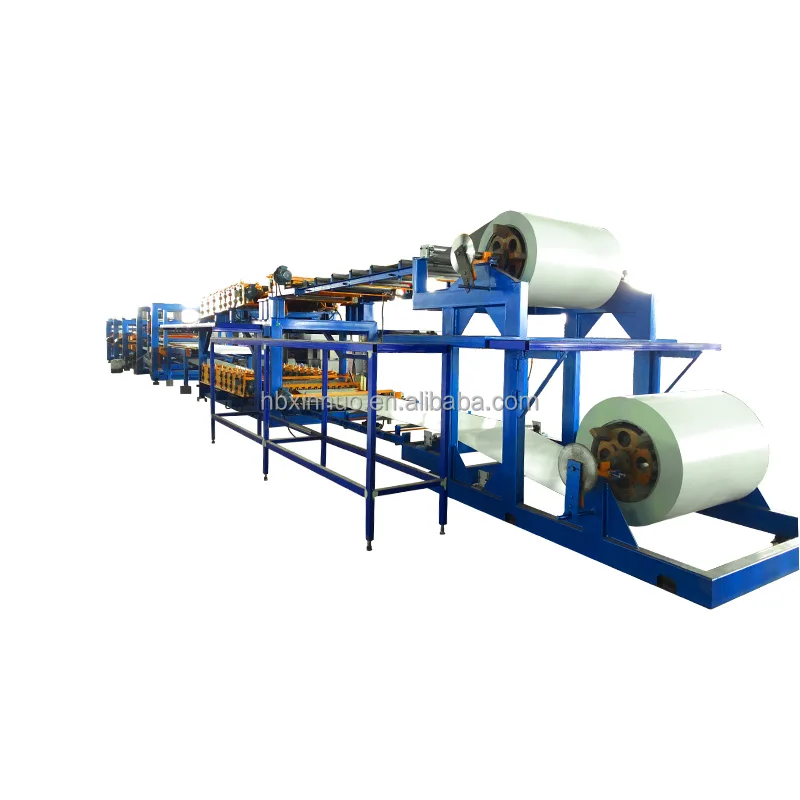

| A'a. | babban siga na Sandwich panel kafa inji line | ||

| 1 | Dace da aiwatarwa | Farantin karfe mai launi | |

| 2 | Nisa na farantin | 1000&1200mm | |

| 3 | Rollers | 17-44 layuka | |

| 4 | Girma | 38.0*2.25*2.5m | |

| 5 | Ƙarfi | 30 kw | |

| 6 | Kauri na farantin | 0.3-0.8mm | |

| 7 | Yawan aiki | 2-6m/min | |

| 8 | Diamita na abin nadi | Φ90mm | |

| 9 | Nauyi | Kusan 15 T | |

| 10 | Wutar lantarki | 380V 50Hz 3 matakai | |

| 11 | Material na yankan farantin | Cr12 | |

| 12 | Gudanar da daidaito | A cikin 1.00mm | |

| 13 | Tsarin sarrafawa | PLC iko | |

| sandwich panel matsayin | |

| Tsawon | Tsawon Min yanke: 3 m Matsakaicin tsayin stacker: 15 m |

| albarkatun albarkatun kasa | |

| Kauri mai kauri | 0.4 ~ 0.6mm (ƙara saman ya kamata ya zama lebur, babu baka da sauran matsalolin saman.) |

| Material coil samar da ƙarfi | 235MPa |

| Material coil max nisa | duba cikakken zanen bayanin martaba. |

| Material coil max nauyi | 5 T |

| Material coil diamita na ciki | Φ508, Φ610 mm |

| EPS core abu | |

| yawa | ≥18Kg/m3 |

| daidai gwargwado | ≤1mm/m |

| digiri | ≤3mm/m |

| panel surface | kamata yayi flat babu lebur digiri ne ≤1.5mm/m, |

| sanwicin panel tsawon | fiye da mita 5 |

| kayan ulu | |

| tsawon fiber | ≥100mm |

| cubage yawa | ≥100Kg/m3 |

| sanwicin panel tsawon | ≥3 mita |

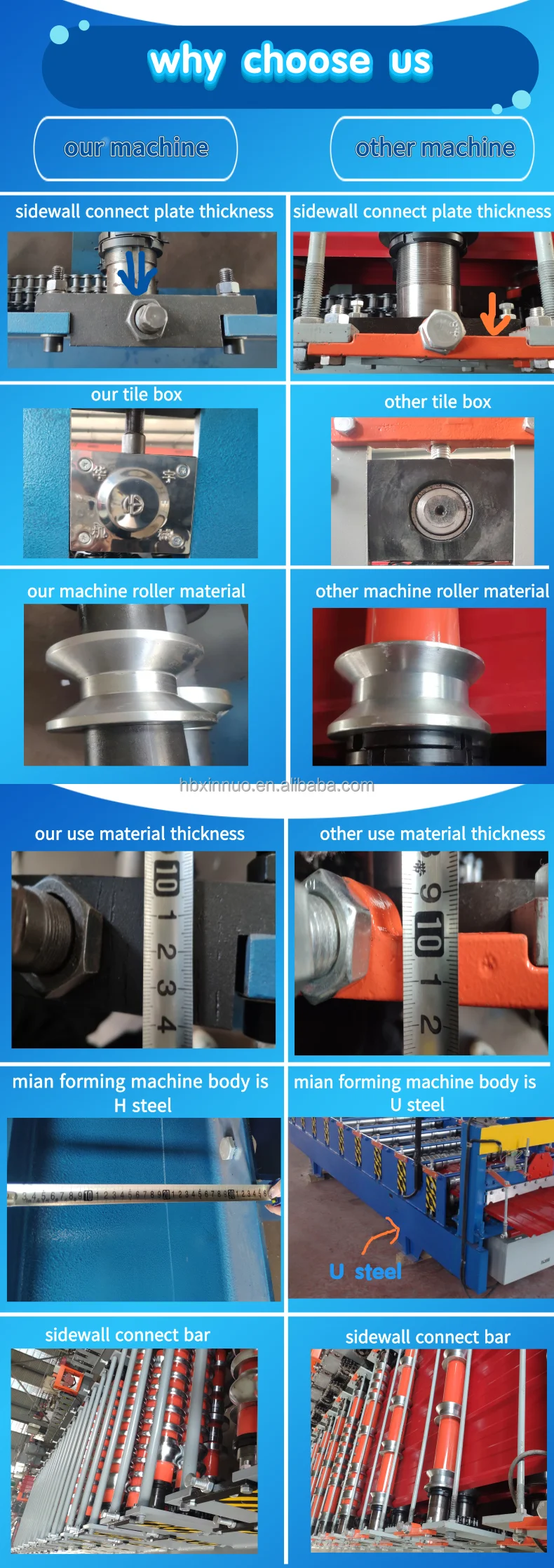

Me Yasa Zabe Mu

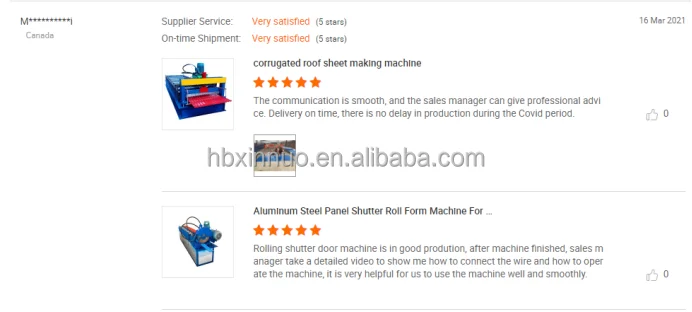

Sharhin Abokin Ciniki

Shiryawa & Bayarwa

| Cikakkun bayanai: | Babban injin tsirara ne, akwatin sarrafa kwamfuta yana cike da firam ɗin katako. |

| Babban injin yana tsirara a cikin akwati, akwatin sarrafa kwamfuta yana cike da marufi na katako. | |

| Bayanin Isarwa: | Kwanaki 20 |

Amfaninmu

BABBAR CNC MILLING MASHIN

z-look atomatik hada sandwich panel yin injialuminum sanwici panel yi linewani tsiro na musamman a lardin Hebei. Yana niƙa dukan firam ɗin kai tsaye. Injin niƙa na iya sa babban saman injin ɗin ya yi laushi kuma injin ɗin ya fi kamala. z-look atomatik hada sandwich panel yin inji aluminum sanwici panel yi line

MASHIN HARBOKI

z-look atomatik composite sanwici panel yin inji aluminum sanwici panel kera layin iya rike da dukan inji frame ko sassa, yin tsatsa surface mai tsabta da kuma santsi surface na samfurin ƙara adhesion.z-look atomatik hada sandwich panel yin inji aluminum sanwici panel yin inji aluminum sanwici panel. yi layi

NEW CNC MILLING

z-look atomatik hada sandwich panel yin inji aluminum sanwici panel ƙera line yin backboard na purlin inji, kuma yin ramukan a kan backboard. Wannan injin niƙa zai iya niƙa allon baya fiye da matakin, wurin rami ya fi daraja. Wannan na iya sa abin nadi ya ƙara matakin bayan shigarwa, sannan purlin zai zama madaidaiciya.

Tsarin injina

z-look atomatik hada sandwich panel yin inji aluminum sanwici panel yi line, da high daraja CNC grinders da milling inji, yi rollers da shafts na inji.Bayan samar, da ƙwararrun injiniya don duba idan wadannan ne m.

Daga nadi ɗaya zuwa na'ura ɗaya, muna yin kowane mataki a hankali don tabbatar da ingancin.

KASAR LANTARKI

Duk tsarin kula da inji mu

yi da kanmu. muna da ƙwararren injiniya don tsarawa da yin tsarin sarrafawa. z-look atomatik hada sandwich panel yin inji aluminum sanwici panel kera layin iya tabbatar da bayan-sale sabis, lokacin da abokin ciniki da matsala tare da iko, za mu iya warware shi dace.

KAYAN FASHIN MAHALI

z-look atomatik hadaddiyar sandwich panel yin inji aluminum sandwich panel ƙera layin lantarki feshin kayan aikin ya dace da ka'idojin kare muhalli na gwamnatin kasar Sin kuma yana ba da tabbacin lokacin isar da injin.

Bayanin Kamfanin

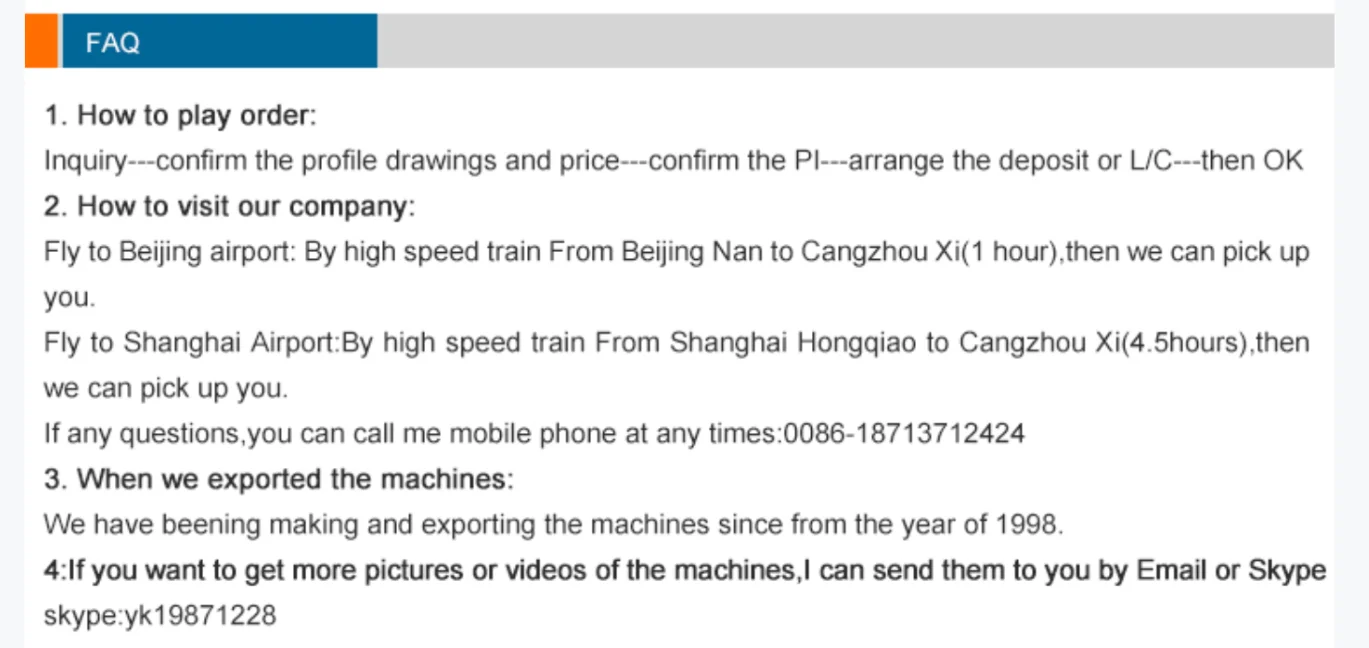

FAQ

♦ BAYANIN KAMFANI:

Hebei Xinnuo Roll Kafa Machine Co., Ltd., ba kawai samar da iri daban-daban na sana'a yi yi inji, amma kuma ci gaba da fasaha atomatik yi kafa samar Lines, C & Z siffar purline inji, babbar hanya Guardrail yi kafa inji Lines, sanwici panel samar Lines, decking. kafa inji, injunan keel haske, rufe slat kofa kafa inji, downpipe inji, gutter inji, da dai sauransu.

Amfanin Ƙirƙirar Ƙarfe Ƙarfe

Akwai fa'idodi da yawa na yin amfani da ƙira don ayyukanku:

- Tsarin ƙirƙira nadi yana ba da damar ayyuka kamar naushi, notching, da walda don yin aiki cikin layi. An rage ko kawar da farashin aiki da lokacin aiki na biyu, rage farashin sashi.

- Roll form kayan aiki damar don wani babban mataki na sassauci. Saitin nau'ikan nau'ikan nadi guda ɗaya zai yi kusan kowane tsayi na ɓangaren giciye ɗaya. Ba a buƙatar saitin kayan aiki da yawa don sassa daban-daban na tsayi.

- Zai iya samar da mafi kyawun iko fiye da sauran matakan ƙirƙira ƙarfe masu fafatawa.

- Maimaituwa yana da mahimmanci a cikin tsari, yana ba da damar sauƙin haɗa sassan nadi a cikin samfuran da aka gama, da rage matsaloli saboda haɓaka haɓaka "misali".

- Ƙirƙirar ƙira yawanci tsari ne mai girma.

- Ƙirƙirar Roll yana ba abokan ciniki kyakkyawan ƙarewa. Wannan ya sa mirgine forming wani kyakkyawan zaɓi don kayan ado bakin karfe sassa ko ga sassa na bukatar gama kamar anodizing ko foda shafi. Har ila yau, ana iya jujjuya rubutu ko tsari a cikin farfajiya yayin ƙirƙirar.

- Ƙirƙirar mirƙira yana amfani da kayan aiki da kyau fiye da sauran hanyoyin gasa.

- Za a iya haɓaka sifofin da aka kafa na Roll tare da bangon bakin ciki fiye da matakan fafatawa

Ƙirƙirar ƙira wani tsari ne mai ci gaba wanda ke canza ƙarfen takarda zuwa sifar injiniya ta amfani da jeri-nauyi na mated rolls, kowannensu yana yin canje-canje kawai a cikin sigar. Jimlar waɗannan ƙananan canje-canje a cikin sigar siffa ce mai rikitarwa.

-

corrugated panel yi kafa inji

-

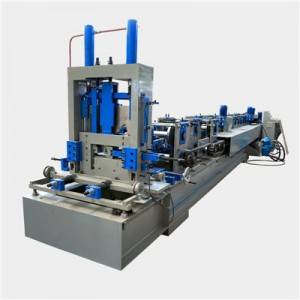

CZ purlin Roll kafa inji

-

Ƙarƙashin katako na kofa mai rufaffiyar na'ura mai ƙira

-

biyu Layer panel yi kafa inji

-

C21 irin tayal latsa Rufin panel yi forming mac ...

-

na'ura mai daidaitawa

-

hudraulic decoiler

-

gutter roll forming inji

-

na'ura mai rufaffiyar kofa

-

atomatik takardar decoiler inji tiles abun yanka m ...

-

atomatik yi forming inji farashin ganga cor ...

-

Atomatik rufi t-grids dimbin yawa karfe mashaya fram ...

-

atomatik stacker

-

atomatik takardar decoiler inji tiles abun yanka m ...

-

c profile karfe yi kafa inji auto cz s ...

-

c purlin inji